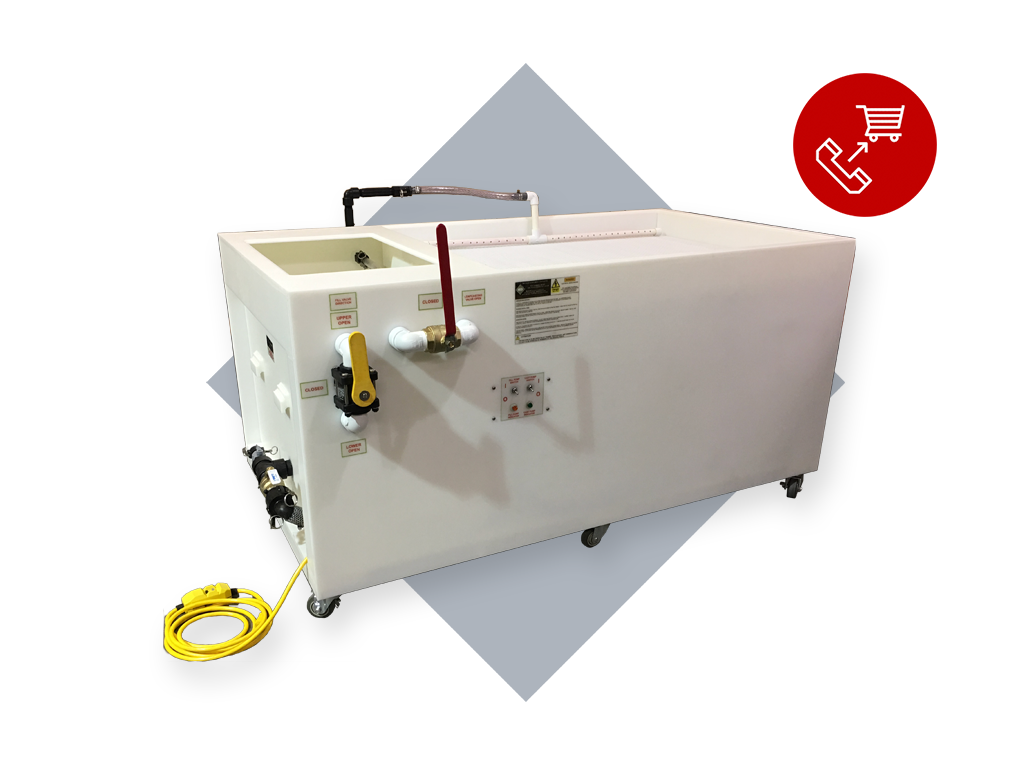

900 Series: MSC Book and Document Leafcaster

Pricing Varies. If $0, then please call for price by ordering a consulation.

Documents with tears, holes, burns, or other losses can be stabilized and protected through a process called Leafcasting. The Leafcasting process uses paper pulp suspended in water and powerful levels of suction to create new paper that is drawn into the losses and integrated with the original paper.

The MSC Book & Document Leafcaster conserves and restores many items including books, printed documents, newspapers, manuscripts and works of art on paper. With a large working area and water capacity, the B&D Leafcaster saves on time and labor over painstaking manual repairs while providing excellent, consistent results.

The Leafcasting process creates new paper at the holes and edges of a paper artifact. Paper pulp suspended in liquid slurry is pulled through a screen by a powerful suction motor. The filter screen prevents pulp from passing through it, leaving pulp deposits in the holes and edges. The excess water is pumped to the Water Holding Tank. The water is reusable for multiple castings. The new pulp binds to the original document, creating a uniform and stable sheet of paper. No adhesives are required. Alternatively, the Leafcaster can be used to cast entire sheets of paper for use in conservation. Even extremely thin gossamer sheets can be cast for use on other documents.

The B&D Leafcaster package includes:

- MSC Book & Document Complete Leafcasting Unit

- Two water suction pumps

- Lockable Casters

- Ground Fault Circuit Interrupter

- PVC spray fill bar

- Removable Water Holding Tank with easy drainage

APPLICATION

Leafcasting mechanically stabilizes paper weakened by holes, ragged borders, or other types of loss. Turn the machine on and turn a valve to start the water flow. Clean water fills the casting tank work area, wetting the documents to be conserved. A prepared pulp mixture is added to the water. With the flip of a switch, the suction pumps are activated, and by turning a valve, the casting tank work area is rapidly drained, removing all of the water but leaving the paper pulp behind, filling in all of the losses and empty areas on the casting tank work area. The casts are removed from the machine, flattened and dried, and the entire process can be quickly reset and repeated for the next casting.

The MSC Book & Document Leafcaster is designed for fast and multi-sheet repair projects. Simple manual controls mean maintenance-free operation compared to Leafcasting machines with hydraulic or pneumatic valves. The design of the machine allows the conservator to concentrate on the casting process, not the mechanical operation of the machine. Casting operations can be repeated as quickly as once per minute. Operator intervention is instantaneous at any step in the casting process.

Pulp mixtures are created and calculated for each specific document. This can be done manually by counting the open squares of the lost area, or the optional MSC PageSizer Software can calculate the loss area and compute the correct slurry mixture automatically.

Acknowledgment

Special thanks go to Mr. Franklin Mowery for his unceasing guidance in this project.

FEATURES

The MSC Book & Document Leafcaster is easy to set up, straight out of the crate. Only minimal assembly required. Constructed of white high-density polyethylene, all of the machine's surfaces are durable, waterproof and maintenance-free. Clean with only soap and water. The cabinet contains a built in casting tank and a removable water holding tank. Included with each machine is an aluminum support, a plastic casting screen, Tyvek masking dam (to reduce the casting area), Reemay polyester sheets for document handling, a plastic hold-down grid with handle, and a cover for the casting tank. Water used in the casting process is recycled, so new water is not needed for repeated castings.

The MSC B&D Leafcaster unit is on locking casters, for easy positioning and locking into place during use. When work is done, cleanup is easy. The casting screens and aluminum support are removable for cleaning and drying. Water can either be stored until the next session in the holding tank, or the drainage valve can be opened and all of the water removed from the machine for long-term storage. The water connection hoses are fitted with quick release connections to allow for easy removal, inspection and cleaning. Extended maintenance consists of cleaning the detachable hoses and the holding and casting tanks periodically.

All MSC Book & Document Leafcasters are equipped with Ground Fault Circuit Interrupter (GFCI). A GFCI is an electrical wiring device that disconnects a circuit, depowering the machine whenever it detects that the electric current is not balanced between the energized conductor and the return neutral conductor. This protects against surges and electrical dangers from spilled water while the Leafcaster is in operation.

ELECTRICAL

220-240, VAC 50/60 Hz 1Ø 3120 watt

| No. | Description | Casting Area | Cabinet Size | ||

| 901-001 | Standard | 64 x 76 cm | 25 x 30 inches | 150 x 74 x 94 cm | 59 x 29 x 37 inches |

| 902-001 | Large | 92 x 122 cm | 36 x 48 inches | 185 x 101 x 92 cm | 73 x 40 x 36 inches |

Documents with tears, holes, burns, or other losses can be stabilized and protected through a process called Leafcasting. The Leafcasting process uses paper pulp suspended in water and powerful levels of suction to create new paper that is drawn into the losses and integrated with the original paper.

The MSC Book & Document Leafcaster conserves and restores many items including books, printed documents, newspapers, manuscripts and works of art on paper. With a large working area and water capacity, the B&D Leafcaster saves on time and labor over painstaking manual repairs while providing excellent, consistent results.

The Leafcasting process creates new paper at the holes and edges of a paper artifact. Paper pulp suspended in liquid slurry is pulled through a screen by a powerful suction motor. The filter screen prevents pulp from passing through it, leaving pulp deposits in the holes and edges. The excess water is pumped to the Water Holding Tank. The water is reusable for multiple castings. The new pulp binds to the original document, creating a uniform and stable sheet of paper. No adhesives are required. Alternatively, the Leafcaster can be used to cast entire sheets of paper for use in conservation. Even extremely thin gossamer sheets can be cast for use on other documents.

The B&D Leafcaster package includes:

- MSC Book & Document Complete Leafcasting Unit

- Two water suction pumps

- Lockable Casters

- Ground Fault Circuit Interrupter

- PVC spray fill bar

- Removable Water Holding Tank with easy drainage

APPLICATION

Leafcasting mechanically stabilizes paper weakened by holes, ragged borders, or other types of loss. Turn the machine on and turn a valve to start the water flow. Clean water fills the casting tank work area, wetting the documents to be conserved. A prepared pulp mixture is added to the water. With the flip of a switch, the suction pumps are activated, and by turning a valve, the casting tank work area is rapidly drained, removing all of the water but leaving the paper pulp behind, filling in all of the losses and empty areas on the casting tank work area. The casts are removed from the machine, flattened and dried, and the entire process can be quickly reset and repeated for the next casting.

The MSC Book & Document Leafcaster is designed for fast and multi-sheet repair projects. Simple manual controls mean maintenance-free operation compared to Leafcasting machines with hydraulic or pneumatic valves. The design of the machine allows the conservator to concentrate on the casting process, not the mechanical operation of the machine. Casting operations can be repeated as quickly as once per minute. Operator intervention is instantaneous at any step in the casting process.

Pulp mixtures are created and calculated for each specific document. This can be done manually by counting the open squares of the lost area, or the optional MSC PageSizer Software can calculate the loss area and compute the correct slurry mixture automatically.

Acknowledgment

Special thanks go to Mr. Franklin Mowery for his unceasing guidance in this project.

FEATURES

The MSC Book & Document Leafcaster is easy to set up, straight out of the crate. Only minimal assembly required. Constructed of white high-density polyethylene, all of the machine's surfaces are durable, waterproof and maintenance-free. Clean with only soap and water. The cabinet contains a built in casting tank and a removable water holding tank. Included with each machine is an aluminum support, a plastic casting screen, Tyvek masking dam (to reduce the casting area), Reemay polyester sheets for document handling, a plastic hold-down grid with handle, and a cover for the casting tank. Water used in the casting process is recycled, so new water is not needed for repeated castings.

The MSC B&D Leafcaster unit is on locking casters, for easy positioning and locking into place during use. When work is done, cleanup is easy. The casting screens and aluminum support are removable for cleaning and drying. Water can either be stored until the next session in the holding tank, or the drainage valve can be opened and all of the water removed from the machine for long-term storage. The water connection hoses are fitted with quick release connections to allow for easy removal, inspection and cleaning. Extended maintenance consists of cleaning the detachable hoses and the holding and casting tanks periodically.

All MSC Book & Document Leafcasters are equipped with Ground Fault Circuit Interrupter (GFCI). A GFCI is an electrical wiring device that disconnects a circuit, depowering the machine whenever it detects that the electric current is not balanced between the energized conductor and the return neutral conductor. This protects against surges and electrical dangers from spilled water while the Leafcaster is in operation.

ELECTRICAL

220-240, VAC 50/60 Hz 1Ø 3120 watt

| No. | Description | Casting Area | Cabinet Size | ||

| 901-001 | Standard | 64 x 76 cm | 25 x 30 inches | 150 x 74 x 94 cm | 59 x 29 x 37 inches |

| 902-001 | Large | 92 x 122 cm | 36 x 48 inches | 185 x 101 x 92 cm | 73 x 40 x 36 inches |

1. PURCHASE ORDERS

- Order supplies and equipment directly from Museum Services Corporation. Equipment may be available from local distributors for customers outside the United States. Contact us for information locations of our international distributors.

- Post, telephone, email or fax your purchase orders. Verbal orders should be followed by written confirmation. Purchase orders reduce confusion and errors.

- All recommendations or statements by MSC are based on MSC research and experience and are believed to be reliable, but no guarantee is made for their accuracy. BUYER must determine for itself by preliminary tests or otherwise the suitability of the product for his purpose. MSC warrants that the product conforms to its description; that it will convey good title thereto, that such product(s) will be delivered free from any lawful security interest or encumbrance unknown to BUYER.

2. SHIPMENT AND RETURN OF GOODS

- Notwithstanding the extra measures taken by us to safeguard your order during shipment, protect your investment by inspecting all shipments upon arrival.

- DO NOT SIGN the delivery receipt without noting exceptions for damage or shortages. Note any obvious damage or shortages in the presence of the driver on the “Delivering Carrier’s Report”, “Bill of Lading” or “Air waybill”.

- To protect yourself from concealed damage, always specify on the report or Bill of Lading or Air waybill with the following words. “These goods are received subject to inspection.”

- You have 10 days to report any concealed damage or delayed shipments and file a claim with the carrier. This claim must originate from your office. Follow the delivering company’s freight claim policy exactly. Contact MuseuM Services Corporation for assistance.

- BUYER shall inspect the product upon delivery. BUYER’s failure to give notice of any claim within ten (10) days from date of delivery constitutes a waiver by BUYER with respect thereto.

- Unless otherwise indicated on the invoice, all products are sold EX WORKS and all shipments become the Buyers responsibility upon leaving our shipping dock (f.o.b. factory). Title and risk of loss of the product sole pass to the BUYER upon SELLER’s delivery to the carrier at point of shipment.

- SELLER reserves the right to suspend or defer future deliveries of product, change the terms of sale or cancel the contract if the financial responsibilities of the BUYER becomes impaired or unsatisfactory to the SELLER

- Neither party shall be liable in any respect for failure or delay in the shipment or acceptance of the product, if hindered or prevented, directly or indirectly, by war, national emergency, inadequate transportation facilities, inability to secure materials, supplies, fuel or power, fire, flood, windstorm, or other acts of God, strikes, lockouts, or other labor disputes, orders or acts of any government agency or authority, whether valid or invalid, or any cause of like or different kind beyond the reasonable control of either party. The quantities so affected shall be deducted from the total quantity purchased by the BUYER.

- All recommendations or statements by MSC are based on MSC research and experience and are believed to be reliable, but no guarantee is made for their accuracy. BUYER must determine for itself by preliminary tests or otherwise the suitability of the product for his purpose. MSC warrants that the product conforms to its description; that it will convey good title thereto, that such product(s) will be delivered free from any lawful security interest or encumbrance unknown to BUYER.

- Damage incurred with parcel carriers. PARCEL POST: Notify MuseuM Services Corporation. We will re-send the package after reporting the loss to the Postal Service. UPS and FedEx - a freight claim must originate from MSC offices. The original packaging must be kept. A local carrier agent will come to your location and inspect the damage. We will then provide instructions for the disposition of the merchandise.

- RETURNED GOODS. Buyer must contact MSC for a return authorization before returning any items.

- HAZARDOUS MATERIALS RETURNS. MSC cannot accept returned hazardous materials. Please dispose of properly.

3. WARRANTY

- Each machine or product manufactured by MuseuM Services Corporation comes with a one year limited warranty under normal use. This warranty covers parts and labor from the date of receipt for one full year.

- MSC makes no warranty that the product is merchantable or fit for any particular purpose. Nor is there any other warranty, express of implied, and except as is expressly provided herein.

- MSC shall not be liable for incidental or consequential damages. MSC’s liability and BUYER’s exclusive remedy for any cause of action arising out of the sales, use, or non-delivery of the product(s) is expressly limited at BUYER’s option to replacement of the nonconforming product at f.o.b. shipping or payment not to exceed the purchase price of the product for which damages are claimed.

- If BUYER does not accept these terms and conditions of sale, BUYER shall notify MSC immediately in writing and shall return any shipped products to MSC at once unopened. BUYER’s failure to so object will assent to such terms and conditions of sale.

- MSC proprietary machines are manufactured and intended for trained art conservators, art restorers, art preservers and not members of the general public.

- MSC has no control over the way its products are used. BUYERS must ascertain that the product is suitable for their intended purpose.

- Prices are subject to change. SELLER reserves the right to adjust prices to reflect changing market conditions.

4. PAYMENT

- No modification or addition of the above terms and conditions of sale shall be effected by the acknowledgement or acceptance by MSC of a purchase order, acknowledgement, release or other forms submitted by Buyer containing other or different terms or conditions.

- Neither party shall claim any modification or amendment or release from any of the above terms and conditions of sale unless the parties have entered into a mutual agreement to that effect, signed by BUYER and SELLER. No other representative is authorized to change any of the above terms and conditions which relate to the products sold or delivered as samples or otherwise.

- Title does not pass to the BUYER until the invoice is paid in full.

- Payment must be made in U.S. dollars drawn on a U.S. Bank.

- Visa, MasterCard and other credit cards are accepted. Credit card payments in amounts greater than $1,000.00USD will incur a three percent (3%) surcharge.

- Bank drafts, international postal money orders, or bank wire transfers are accepted. Contact MSC for bank wire transfer information.

- MuseuM Services Corporation reserves the right to sell its products COD (collect on delivery). In addition, MuseuM Services Corporation reserves the right to require deposits on purchase orders.

5. CRATING & PACKAGING CHARGES

- MSC packages its products for safe transit but charges for this service as incurred.

6. REQUEST FOR PRICE QUOTATION

- Upon request we will provide a written “Price Quotation” valid for up to 60 calendar days from the date of issue.

7. DESIGN MODIFICATIONS

- Equipment and crate dimensions cited in MSC brochures, catalogs, and online publications may change depending on modifications of the equipment, or the size and content of the order. MuseuM Services Corporation reserves the right to make modifications in the form of operational improvements to our equipment when deemed necessary or appropriate.